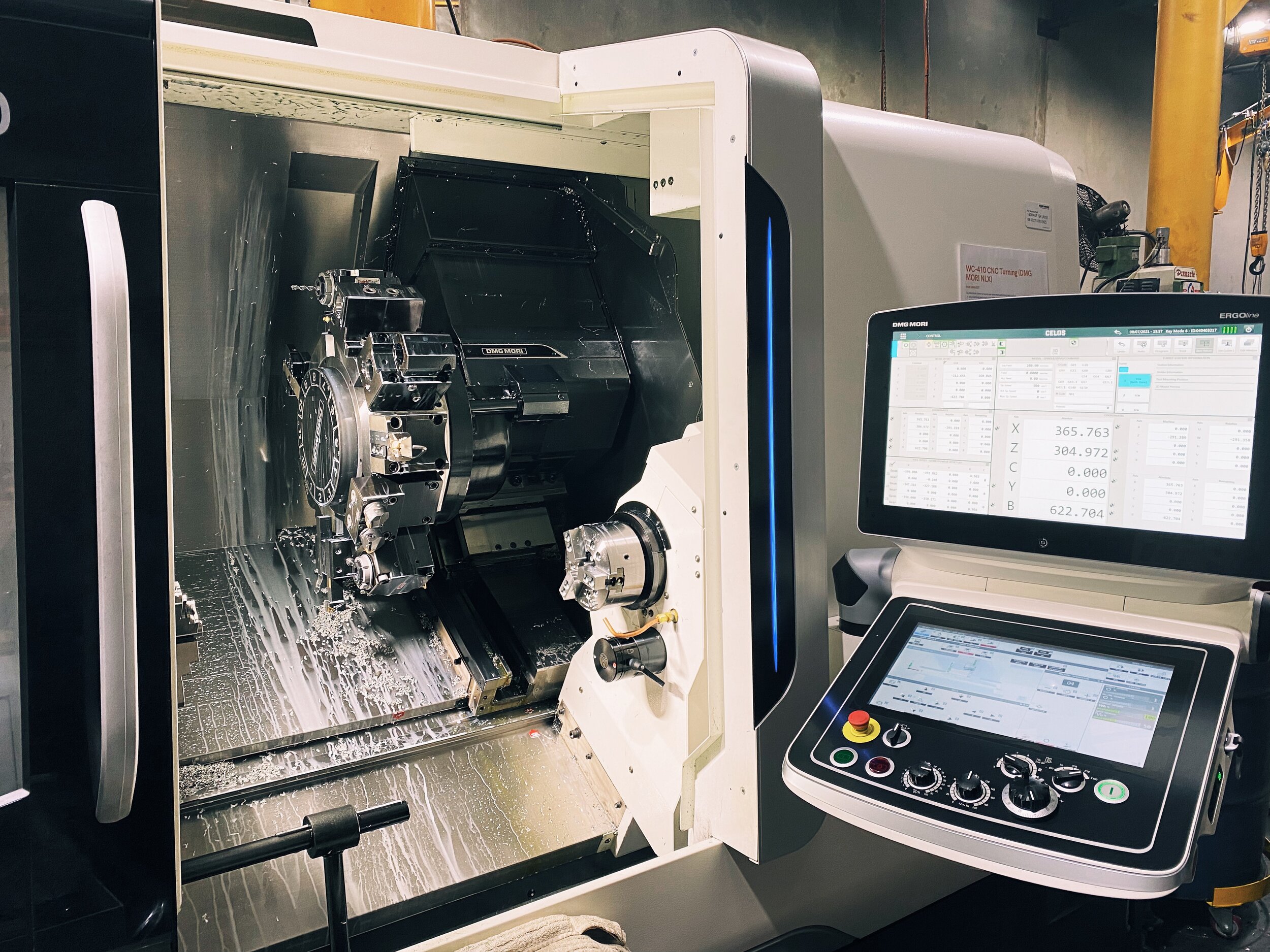

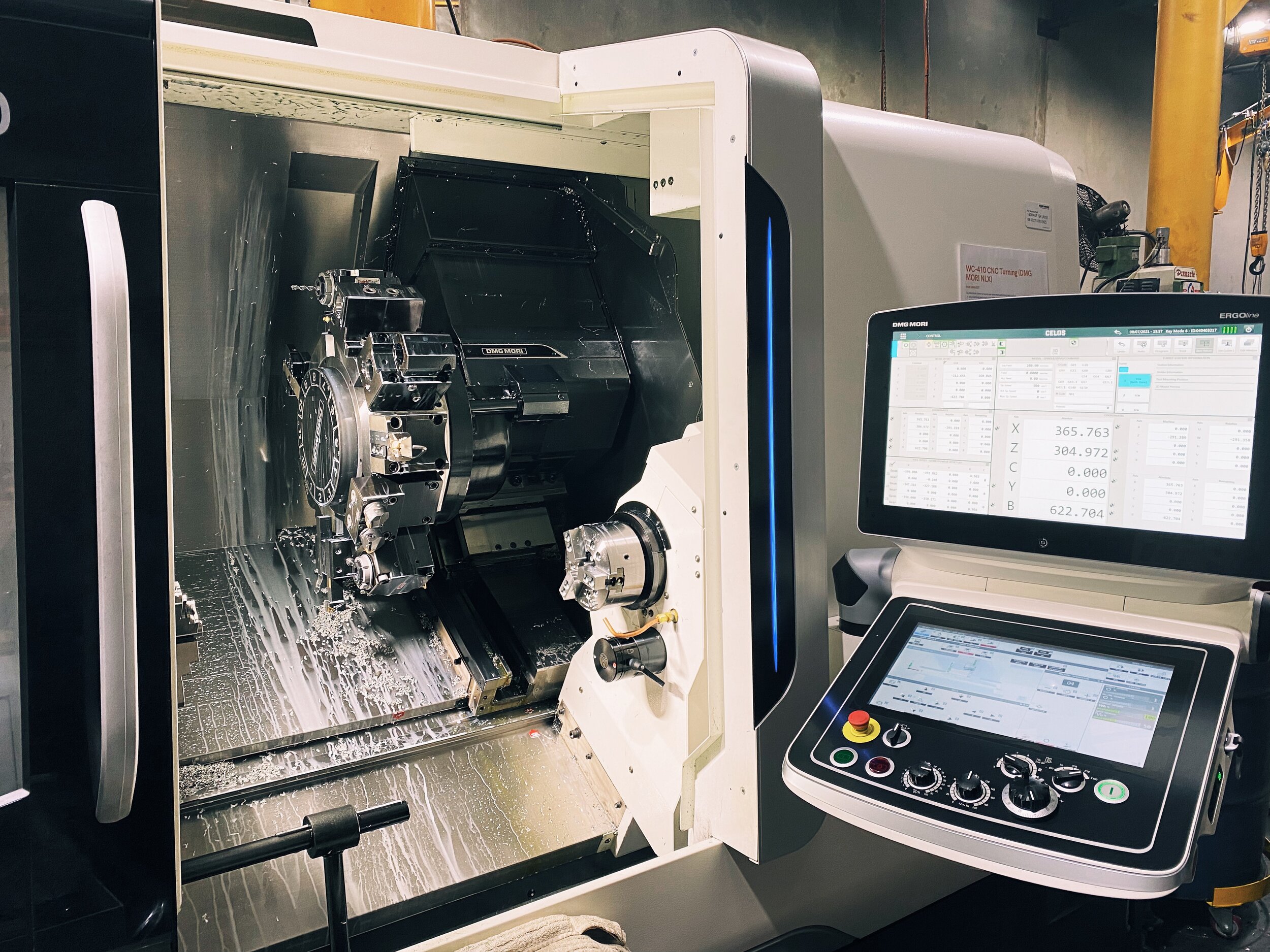

Our DMG MORI NLX 2500

Our DMG MORI NLX 2500

Our DMG MORI NLX 2500

Our DMG MORI NLX 2500

Our DMG MORI NLX 2500

Our DMG MORI NLX 2500

Machining - New Shafts for Electric Motors

Machining - New Shafts for Electric Motors

Machining - Mechanical Repair of Electric Motor Components

Machining - Mechanical Repair of Electric Motor Components

Machining - Replacement Rotor for Electric Motor

Machining - Replacement Rotor for Electric Motor

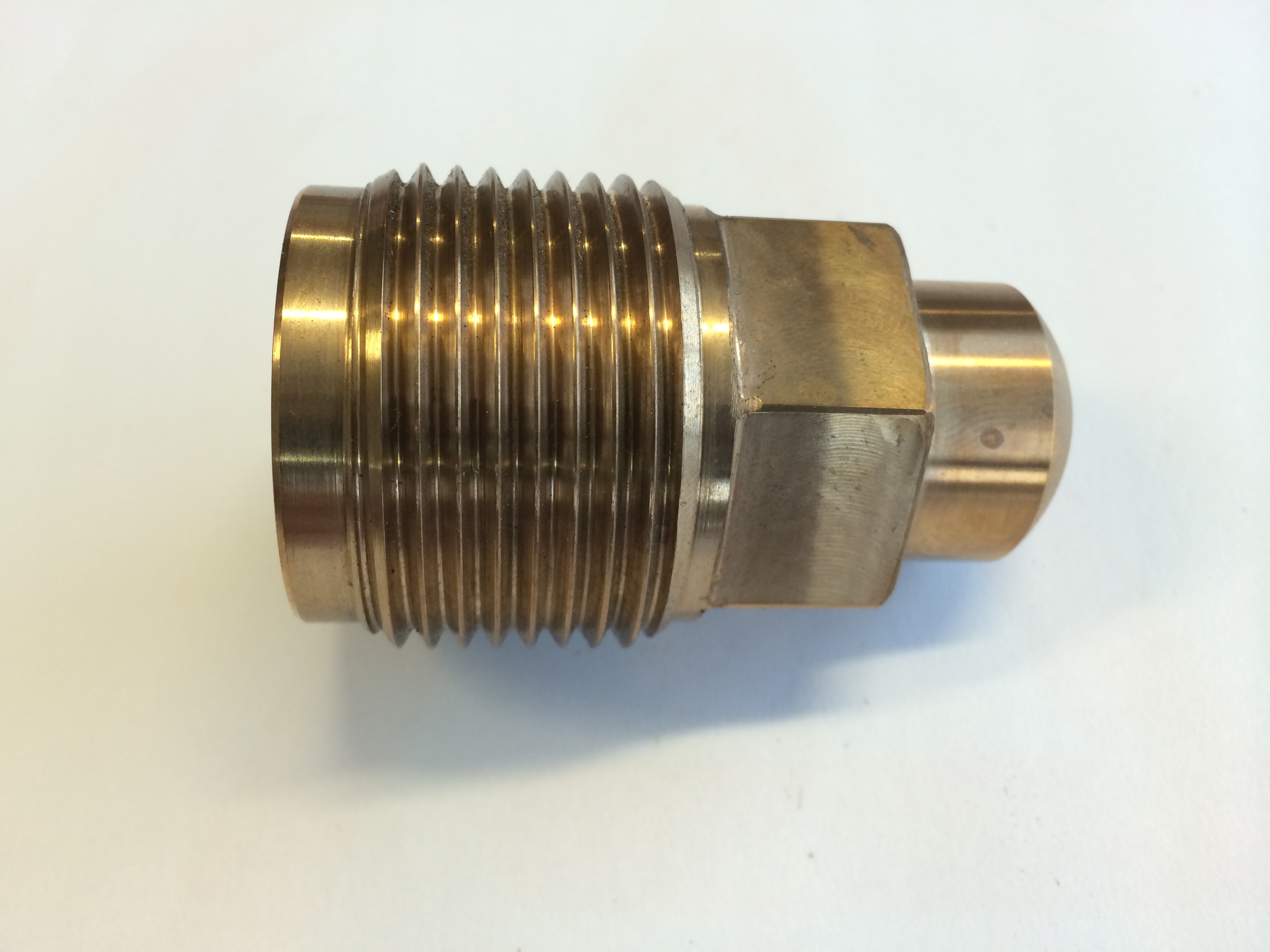

CNC Machining - M100 Nuts

CNC Machining - M100 Nuts

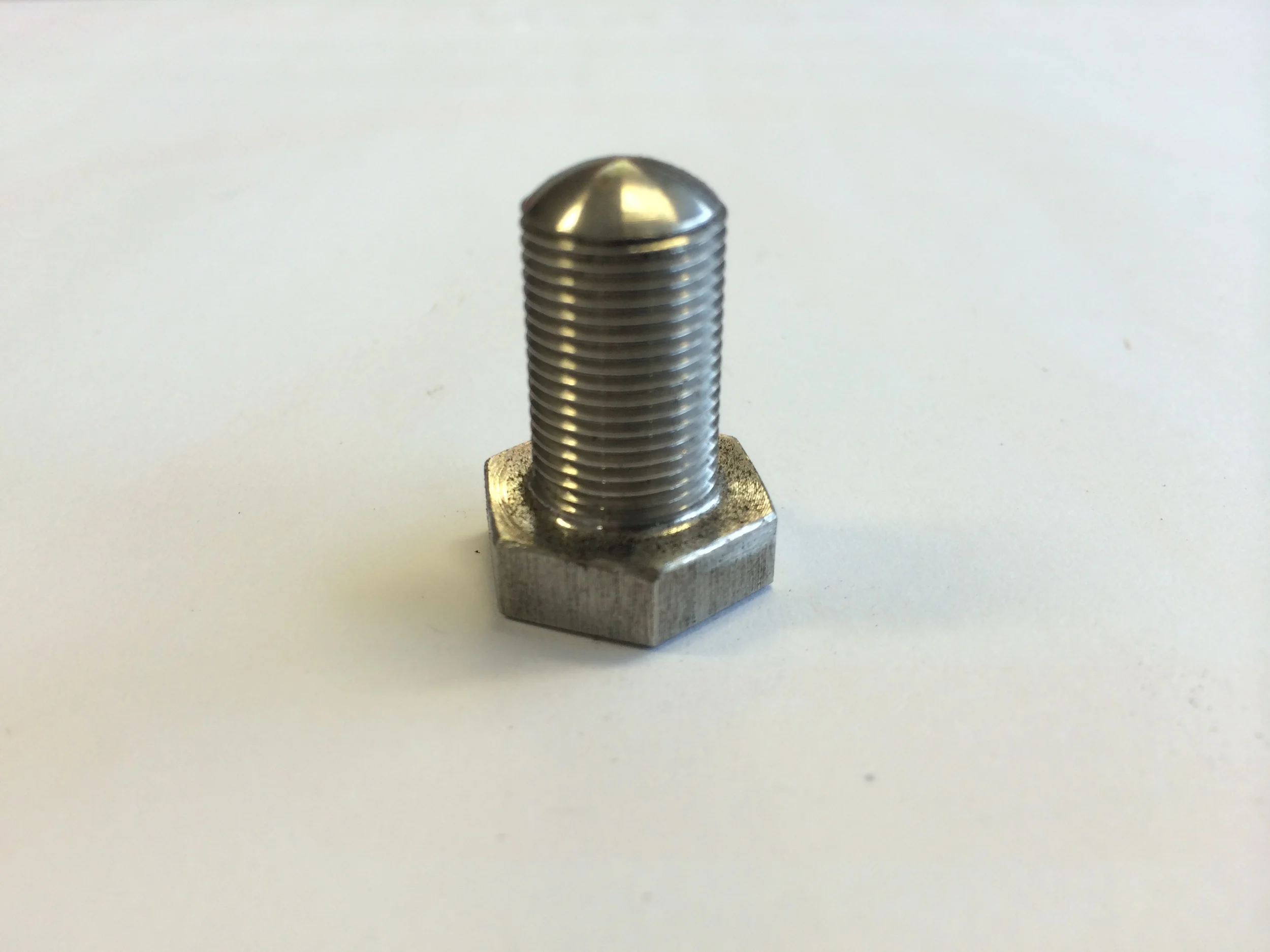

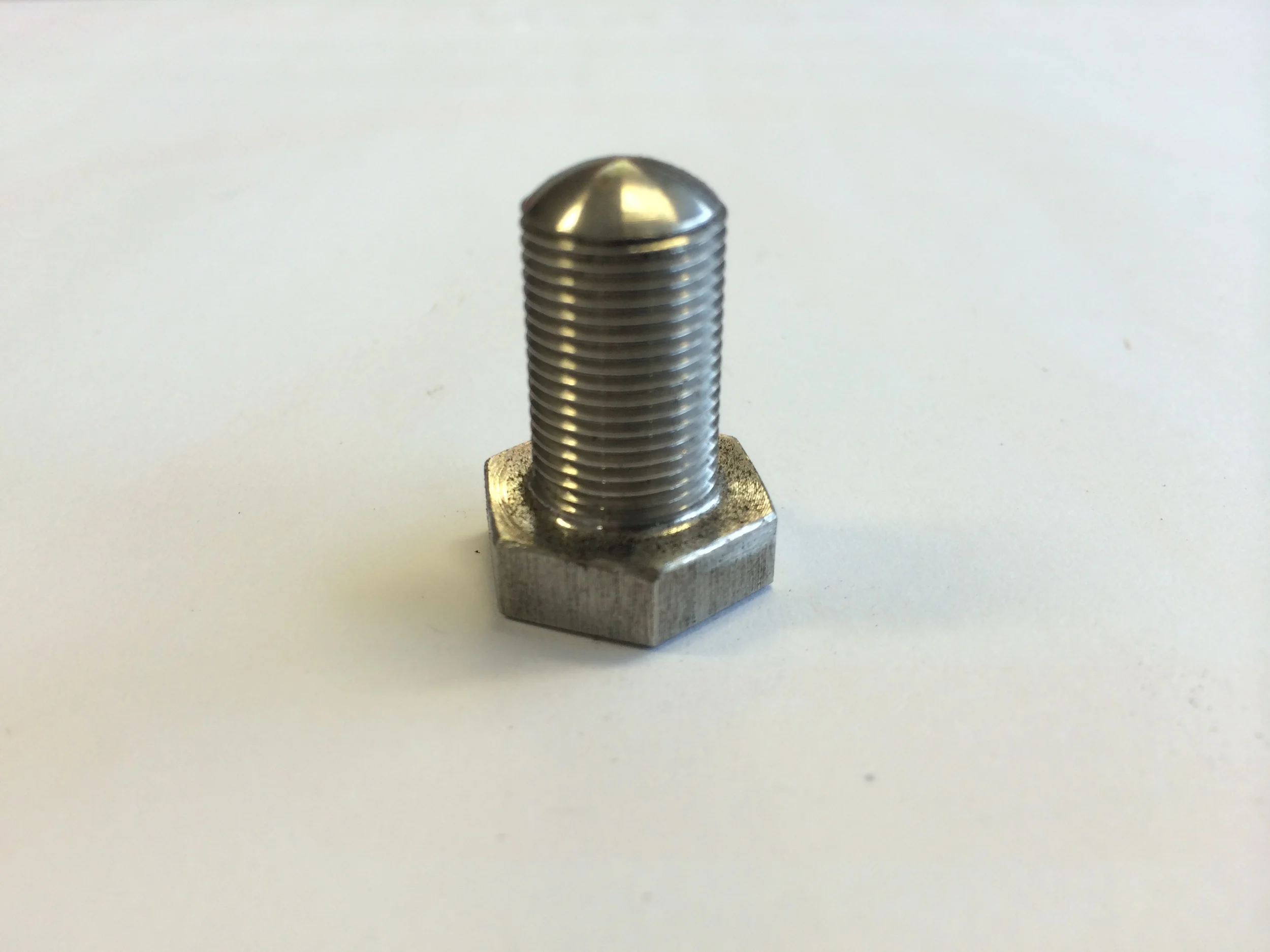

CNC Machining - M100 Studs

CNC Machining - M100 Studs

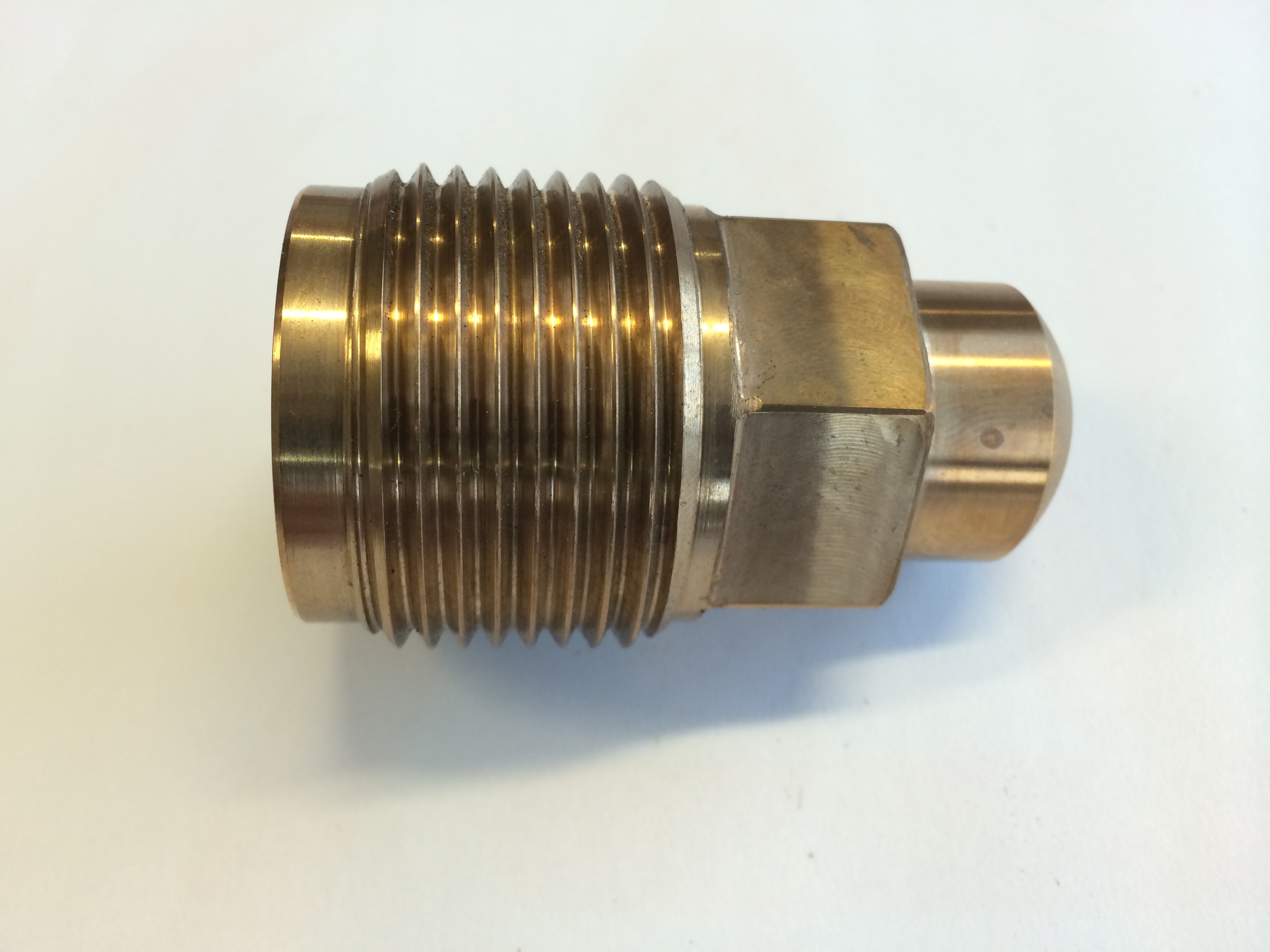

CNC Machining - M100 Nut and Stud

CNC Machining - M100 Nut and Stud

Fabrication - Rotary Saw Components

Fabrication - Rotary Saw Components

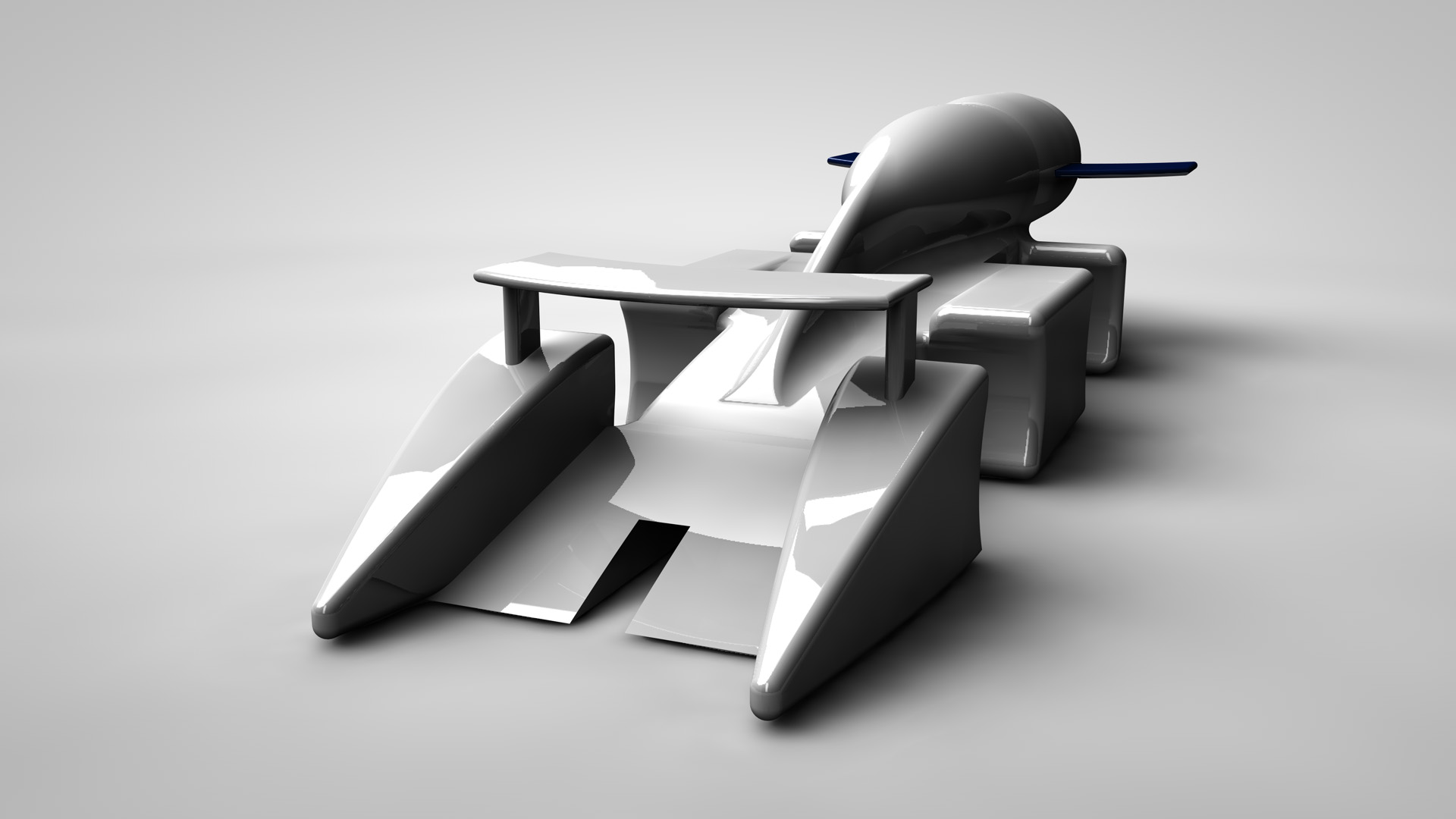

Fabrication - Top Post Assembly Drawing

Fabrication - Top Post Assembly Drawing

Fabrication - Rotary Saw Components

Fabrication - Rotary Saw Components

This photo shows a comparison between the old and new components. In order to produce Engineering Drawings for this job, measurements of the machine taken on-site by our Engineer and compared to the samples provided.

5-Axis Machining of Tool Steel Stamp

5-Axis Machining of Tool Steel Stamp

5-Axis Machining of Tool Steel Stamp

5-Axis Machining of Tool Steel Stamp. As shown with the background of a business card, this job was quite small and largely was machined with a 1 mm ball nose end mill.

5-Axis Machining of Tool Steel Stamp

5-Axis Machining of Tool Steel Stamp

Machined and Fabricated Stainless Steel Fan

Machined and Fabricated Stainless Steel Fan. This was an urgent breakdown that we turned around in 24 hours for our customer. The job required us to supply, machine and fabricate a new fan and shaft as per sample.

In this photo, you can see our part next to the supplied sample.

Stainless Steel Fan and Hub

Machine and Fabricated Stainless Steel Fan. This was an urgent breakdown that we turned around in 24 hours for our customer. The job required us to supply, machine and fabricate a new fan and shaft as per sample.

Machined and Fabricated Stainless Steel Fan

Machined and Fabricated Stainless Steel Fan. This was an urgent breakdown that we turned around in 24 hours for our customer. The job required us to supply, machine and fabricate a new fan and shaft as per sample.

SAF2507 1/2" NPT Plugs

CNC Machined SAF 2507 (Super Duplex) 1/2" NPT Plugs

SAF 2507 1/2" NPT Plugs

CNC machined SAF 2507 (Super Duplex) 1/2" NPT Plugs

SAF 2507 Flanges

CNC Machined SAF 2507 (Super Duplex) Flanges

SAF 2507 Flanges

CNC Machined SAF 2507 (Super Duplex) Flanges

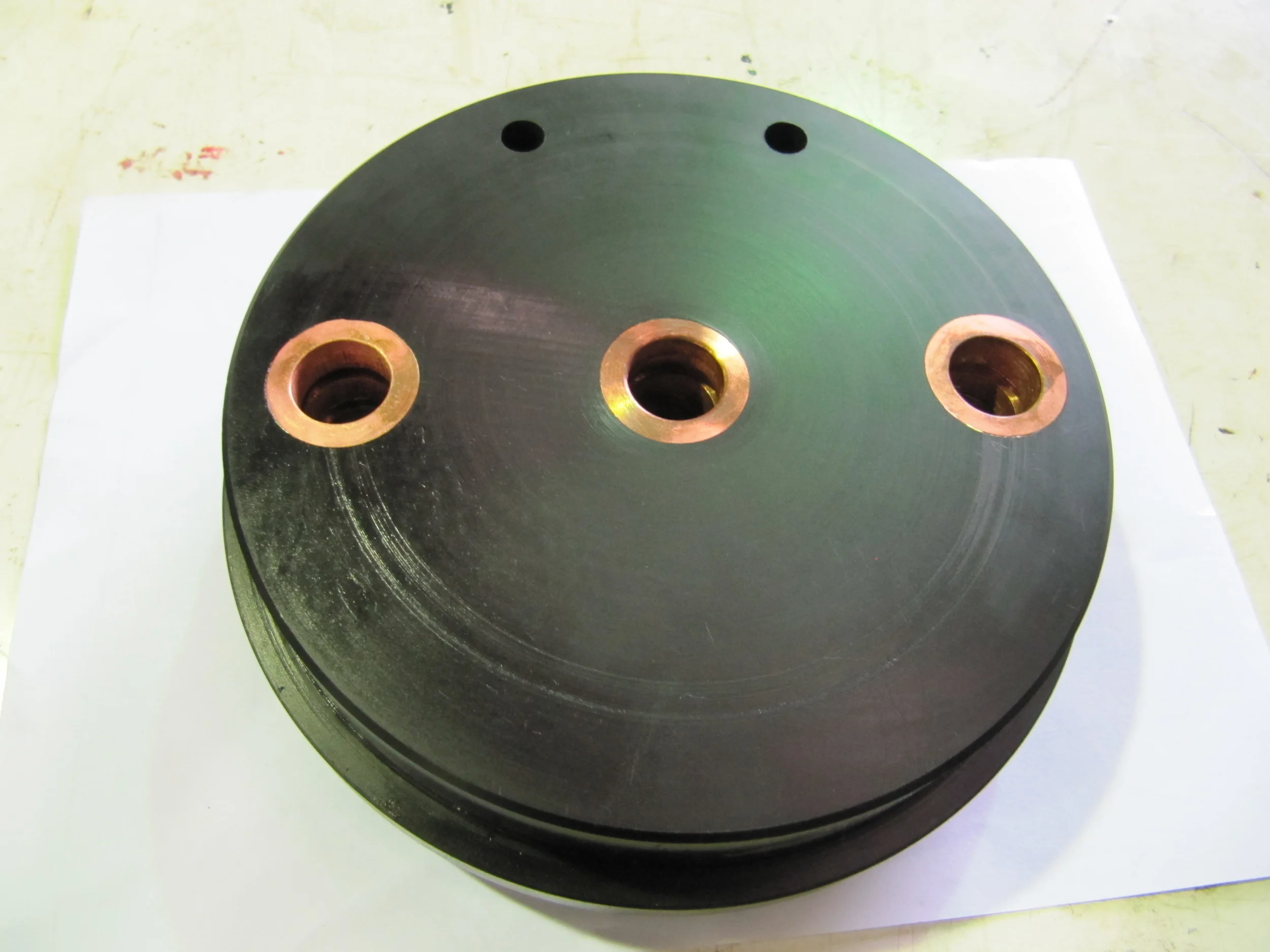

Bore and Bush NDE Bearing Housing

Bore and Bush NDE Bearing Housing and scotch key in place dia 190.00 +0.01 -0.00.

Bore and Bush NDE Bearing Housing

Bore and Bush NDE Bearing Housing. A little difficult to see in this image, but here we have completed a bore and bush on the bearing housing marked with an ‘ x ‘ and arrow.

Bore and Bush NDE Bearing Housing

Bore and Bush NDE Bearing Housing. Dia 150.03 +0.01 -0.00. Another completed bore and bush that did not require scotch keying.

Our HAAS VF3 with 5-Axis Trunnion

Our HAAS VF3 with 5-Axis Trunnion

Our HAAS VF3 with 5-Axis Trunnion

Our HAAS VF3 with 5-Axis Trunnion - set up with our Lang Vise and Base Plate.

Our HAAS VF3 with 5-Axis Trunnion

Our HAAS VF3 with 5-Axis Trunnion

4140 Stock for Tooling Pin

4140 Stock for Tooling Pin

4140 Stock with Sample Pin

4140 Stock with Sample Pin

4140 Tooling Pin

4140 Tooling Pin

4140 Tooling Pin - Sample and New

4140 Tooling Pin - Sample and New

4140 Tooling Pin - Sample and New

4140 Tooling Pin - Sample and New

4140 Tooling Pin - Sample and New

4140 Tooling Pin - Sample and New

CNC Machined Copper Clamps

CNC Machined Copper Clamps

CNC Machined Copper Clamps

CNC Machined Copper Clamps

CNC Machined Copper Clamps

CNC Machined Copper Clamps

Turned Bronze Bushings

Turned Bronze Bushings

Turned and Knurled Part

Turned and Knurled Part

Turned and Knurled Part

Gingerbread Man Tooling

Gingerbread Man Tooling

Gingerbread Man Tooling

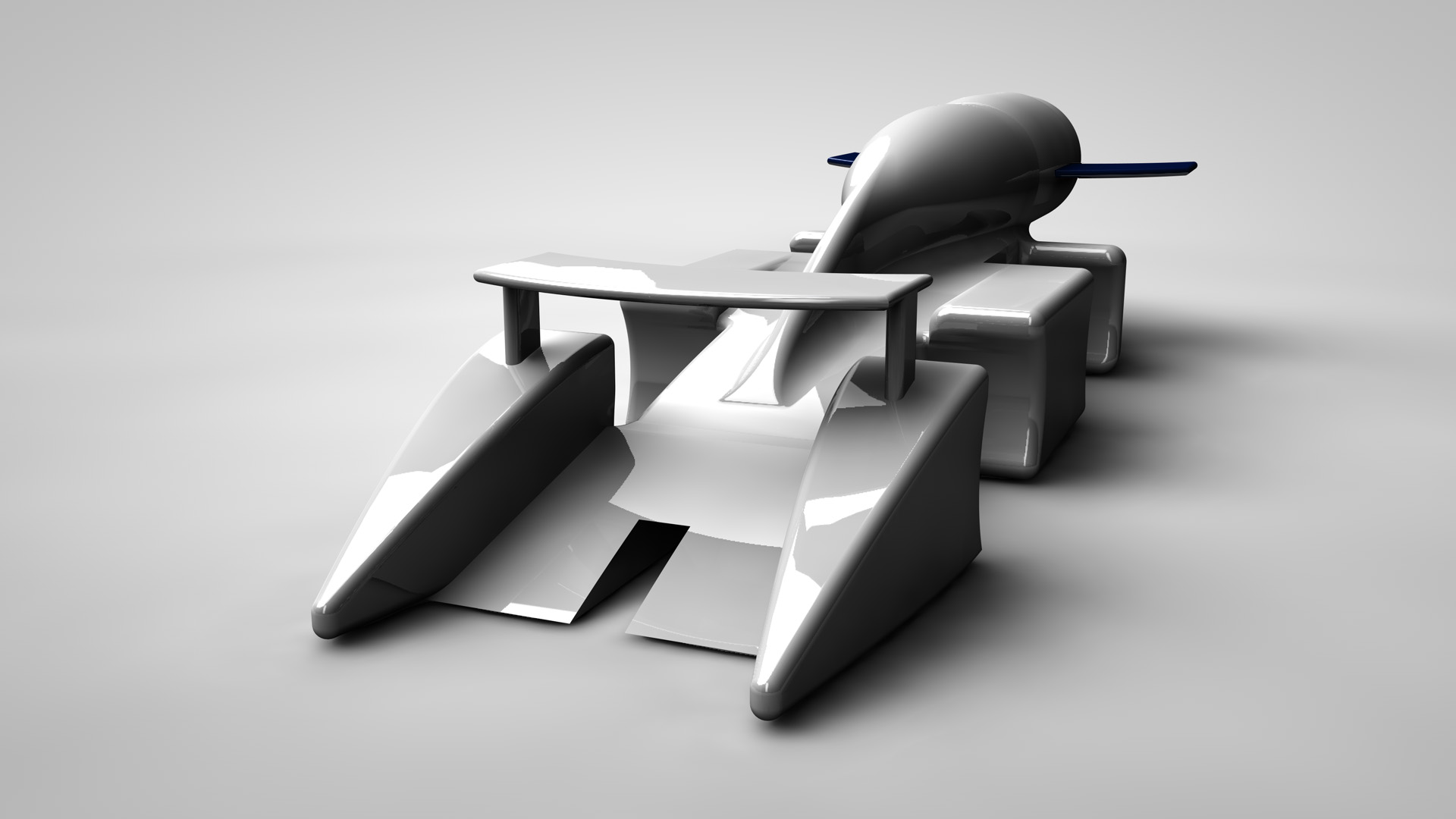

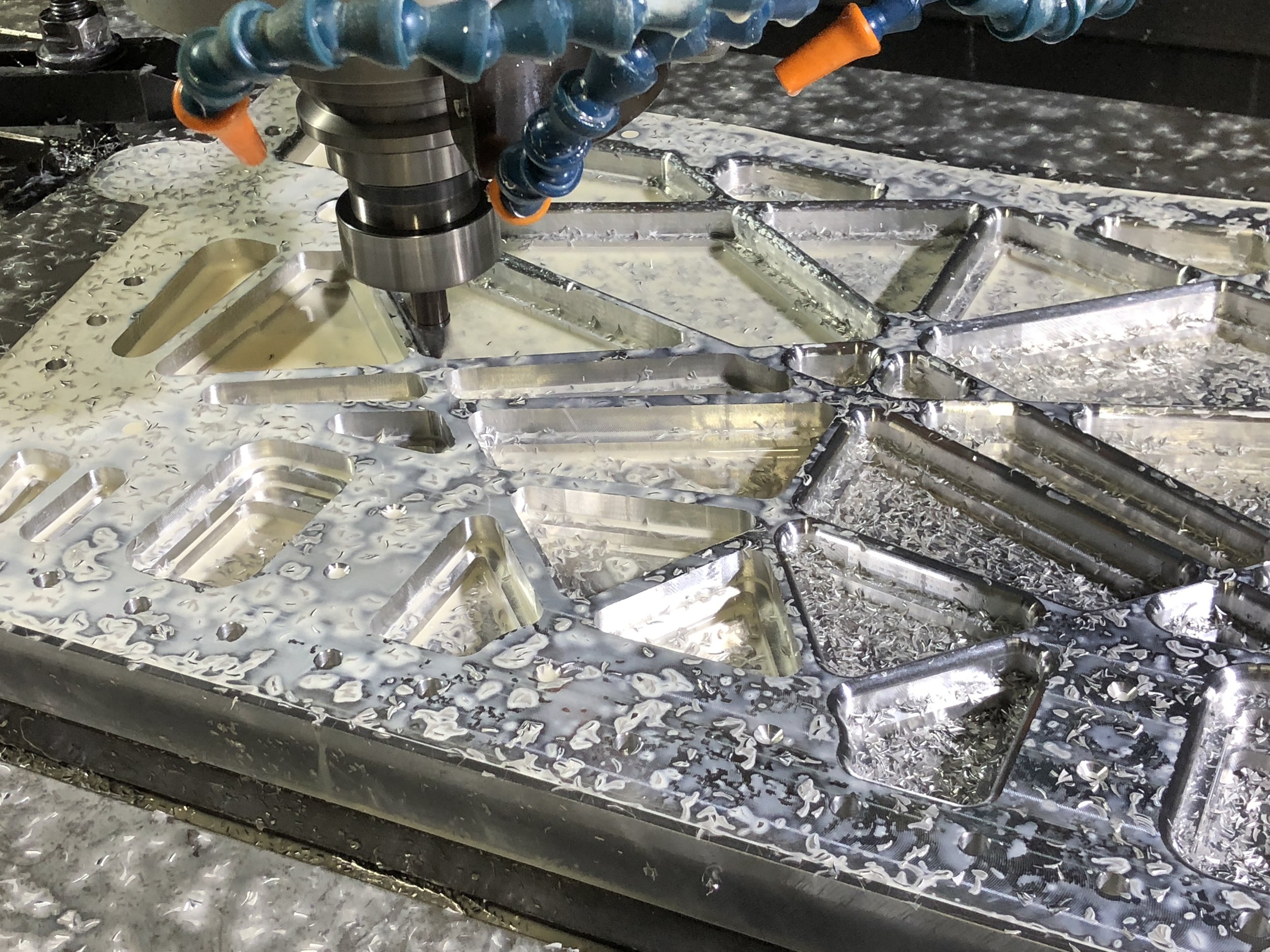

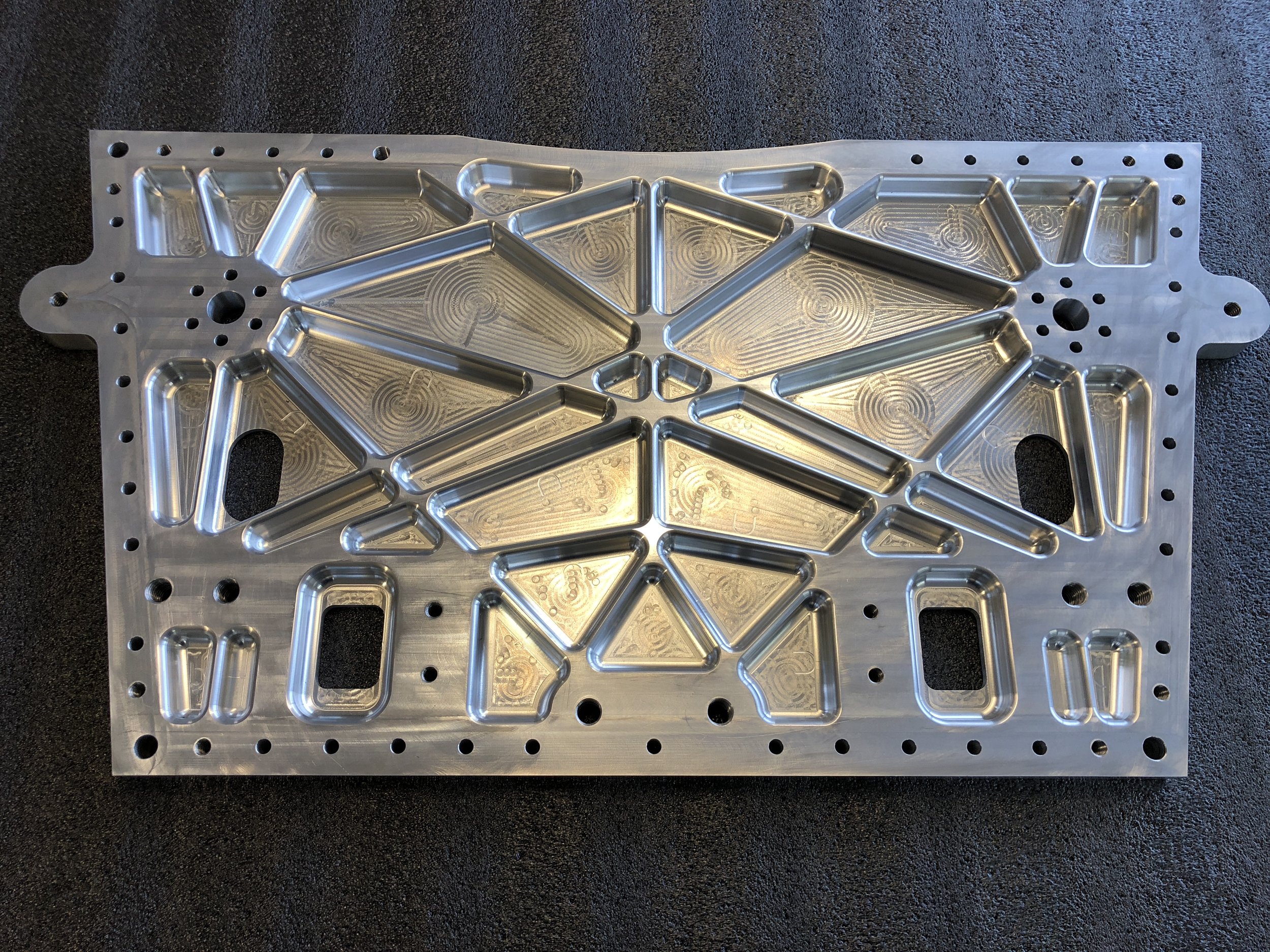

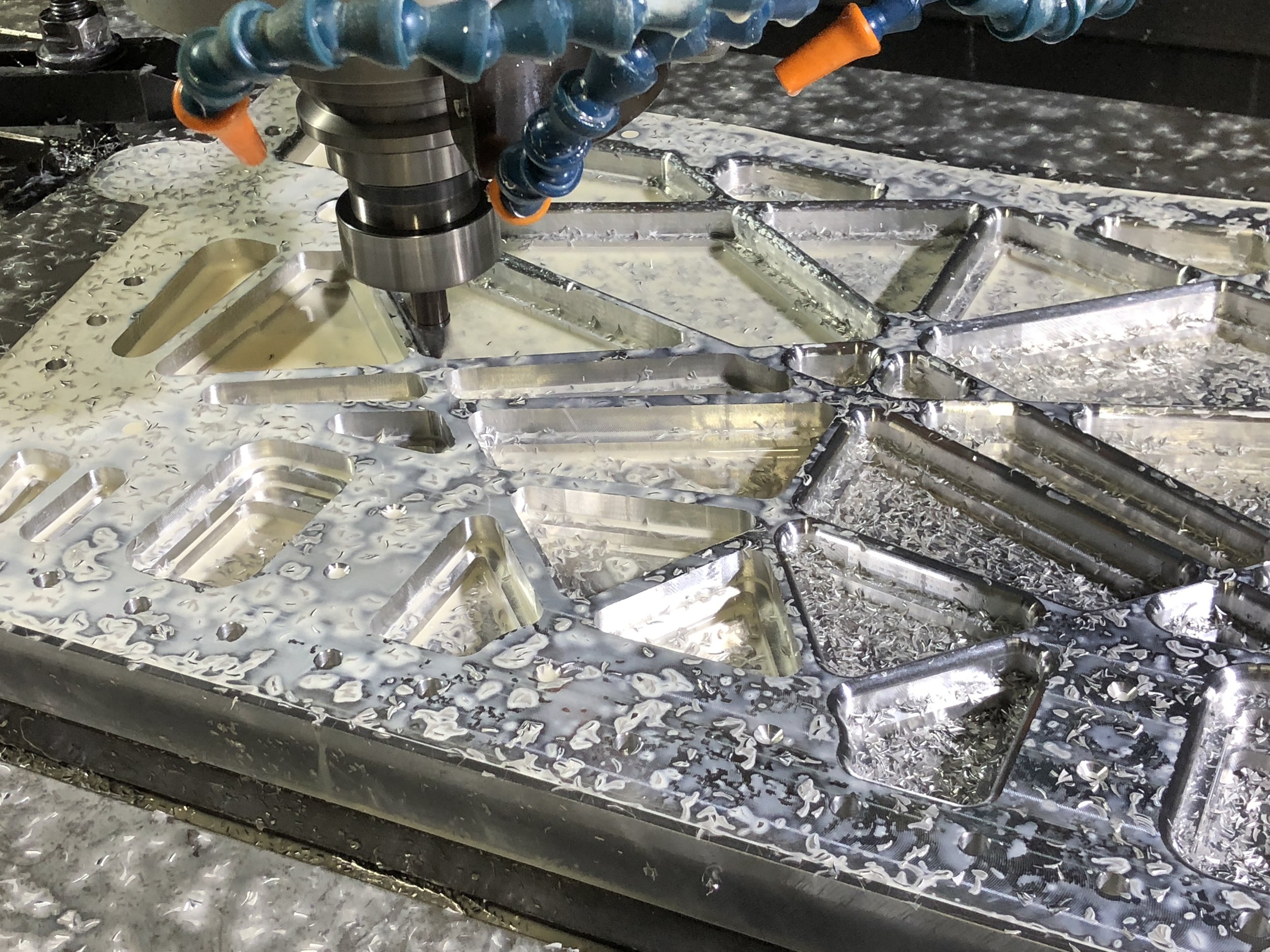

Machining of Engine Plate

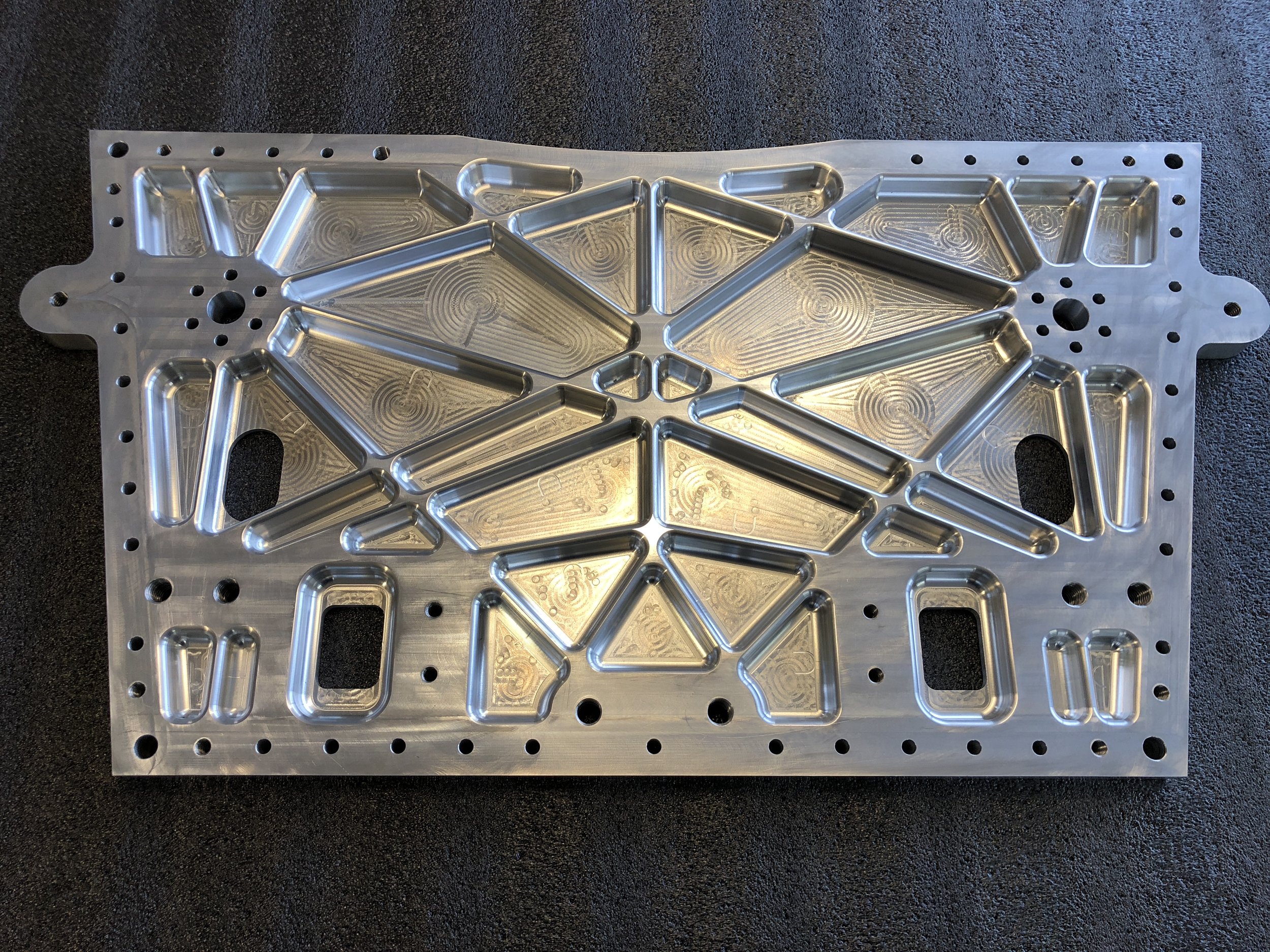

Machined Engine Plate

Machined Engine Plate

Machined Cast Iron Coupling

Supply and machine coupling Dia 254 x 150L (approx dimension). Machine to sample

Machined Cast Iron Coupling

Supply and machine coupling Dia 254 x 150L (approx dimension). Machine to sample.

Machined SAF 2205 Shaft

Machine SAF 2205 shaft, fit to lamination and finish to drawing. Grind lamination to ensure electric motor is running true.

Blister Pack Tooling

Blister Pack Tooling

Blister Pack Tooling

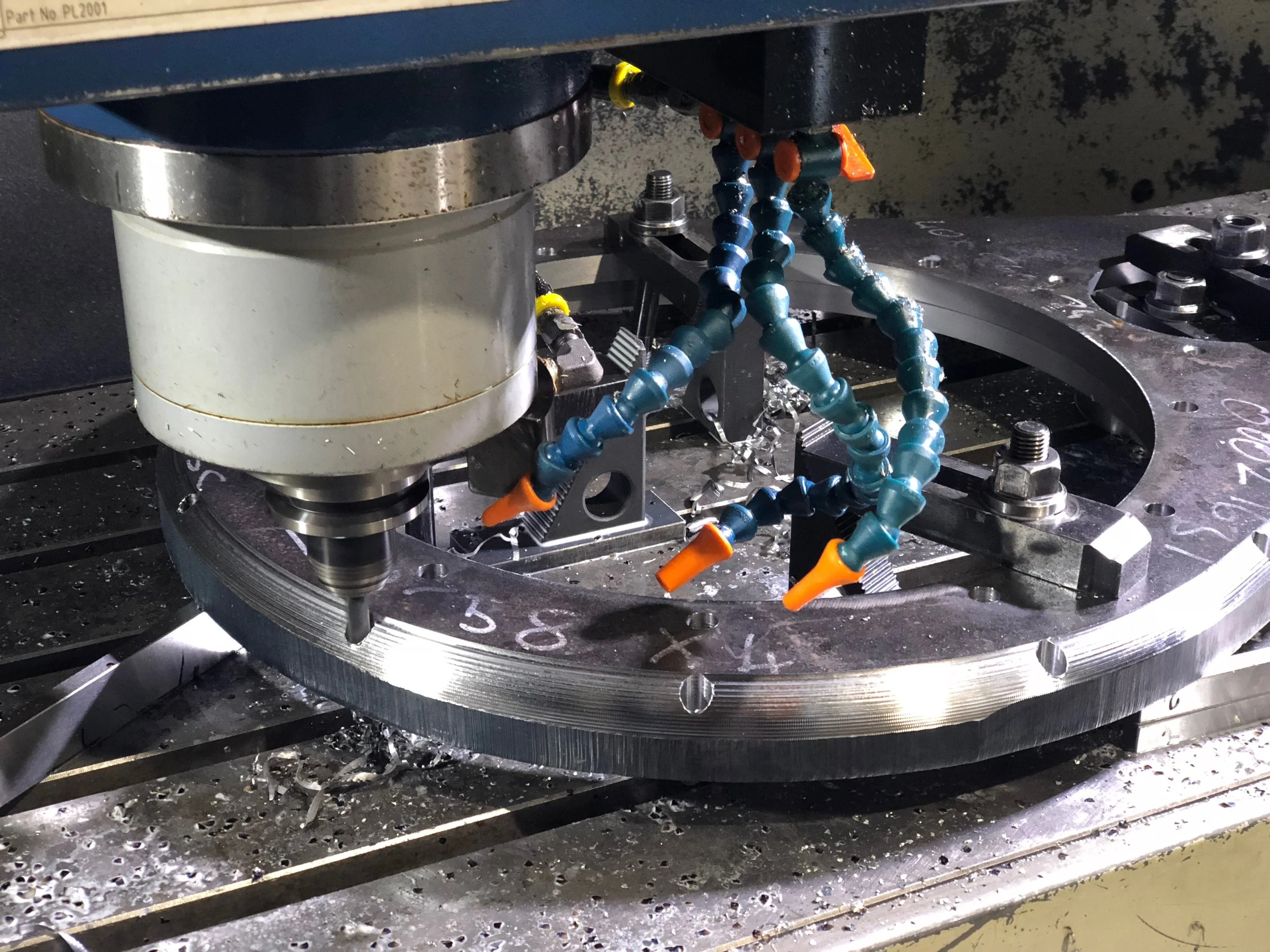

CNC Machining of Pump Components

CNC Machining of Pump Components

CNC Machining of Pump Components

Our DMG CTX with BARLOAD Bar Feeder

Our Factory

Our DMG CTX with BARLOAD Bar Feeder

Machined Wobbler Shafts and Gears

Machined Wobbler Shaft - drilled and bored out broken shafts. Supplied and machined new wobbler shafts to drawing. Removed worn couplings from old shafts. Supplied new keys and assembled new shafts to gears.

Machined Wobbler Shaft

Machined Wobbler Shaft - drilled and bored out broken shafts. Supplied and machined new wobbler shafts to drawing. Removed worn couplings from old shafts. Supplied new keys and assembled new shafts to gears.

Emergency Breakdown - New Drive Shaft

Emergency Breakdown - New Drive Shaft manufactured for customer. Image shows the old drive shaft next to the new drive shaft machined for the customer. Drive shaft features keyways, drilled and tapped holes and spline.

Emergency Breakdown - New Drive Shaft

Emergency Breakdown - New Drive Shaft manufactured for customer. Image shows the new drive shaft next to pump motor. Drive shaft features keyways, drilled and tapped holes and spline.

Emergency Breakdown - New Drive Shaft

Emergency Breakdown - New Drive Shaft manufactured for customer. Image shows the old drive shaft next to the new drive shaft machined for the customer. Drive shaft features keyways, drilled and tapped holes and spline.

Aluminium V-rollers, Shafts and Mount Plates

CNC Turning - Fabrication - Emergency breakdown solution for customer. New aluminium v-rollers with bearings. New shafts, new mount plate and 4 v-rollers supplied. Photo shows old roller (front) and new roller (back).

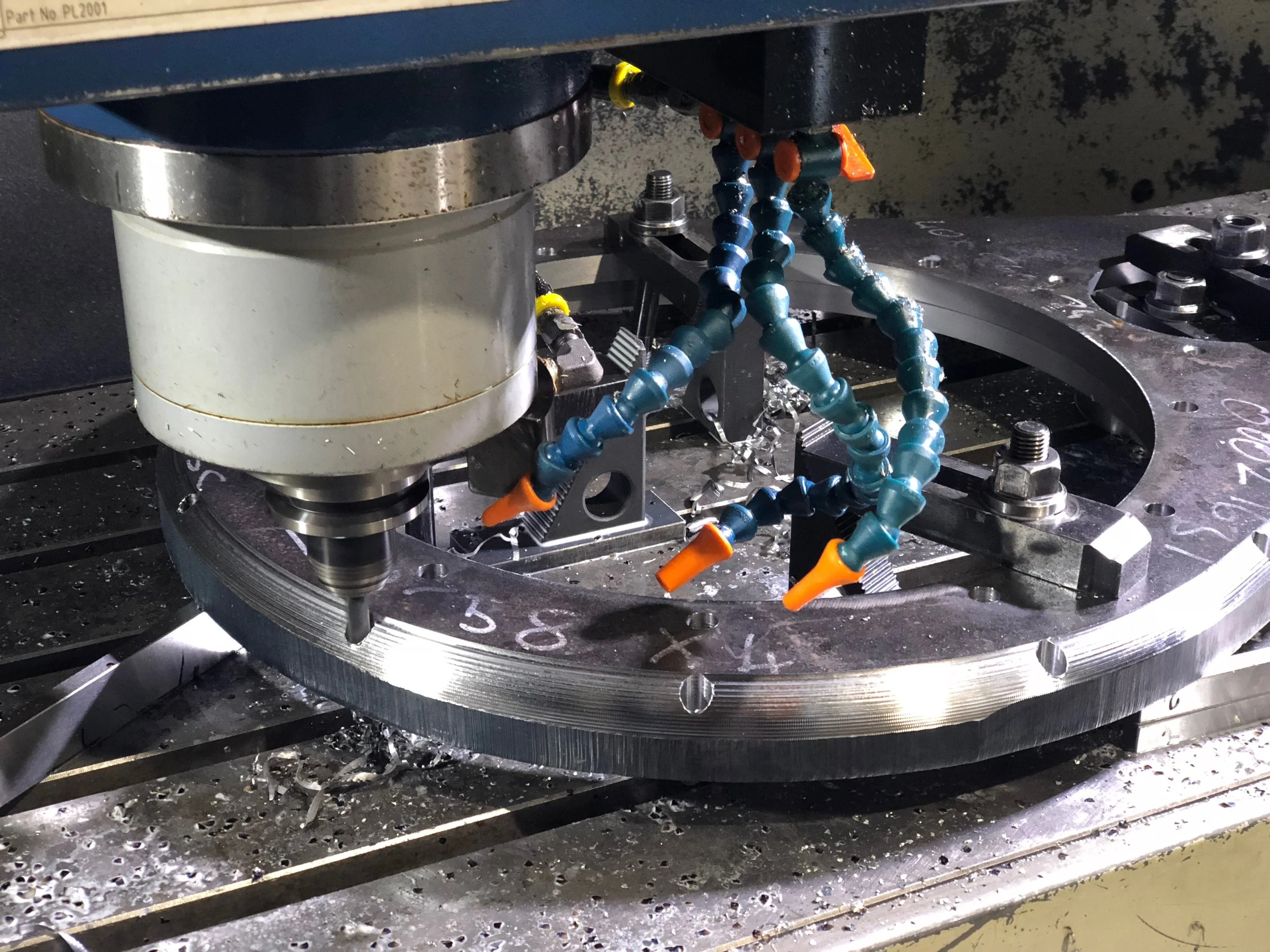

CNC Machining of gearbox housing

CNC Milling - Gearbox Housing - the casing that surrounds the mechanical components of a gear box. It provides mechanical support for the moving components.

Gearbox Housing

Fabrication / CNC Machining - Gearbox housing - the casing that surrounds the mechanical components of a gear box. It provides mechanical support for the moving components.

Gearbox Housing

Fabrication / CNC Machining - Gearbox housing - the casing that surrounds the mechanical components of a gear box. It provides mechanical support for the moving components.

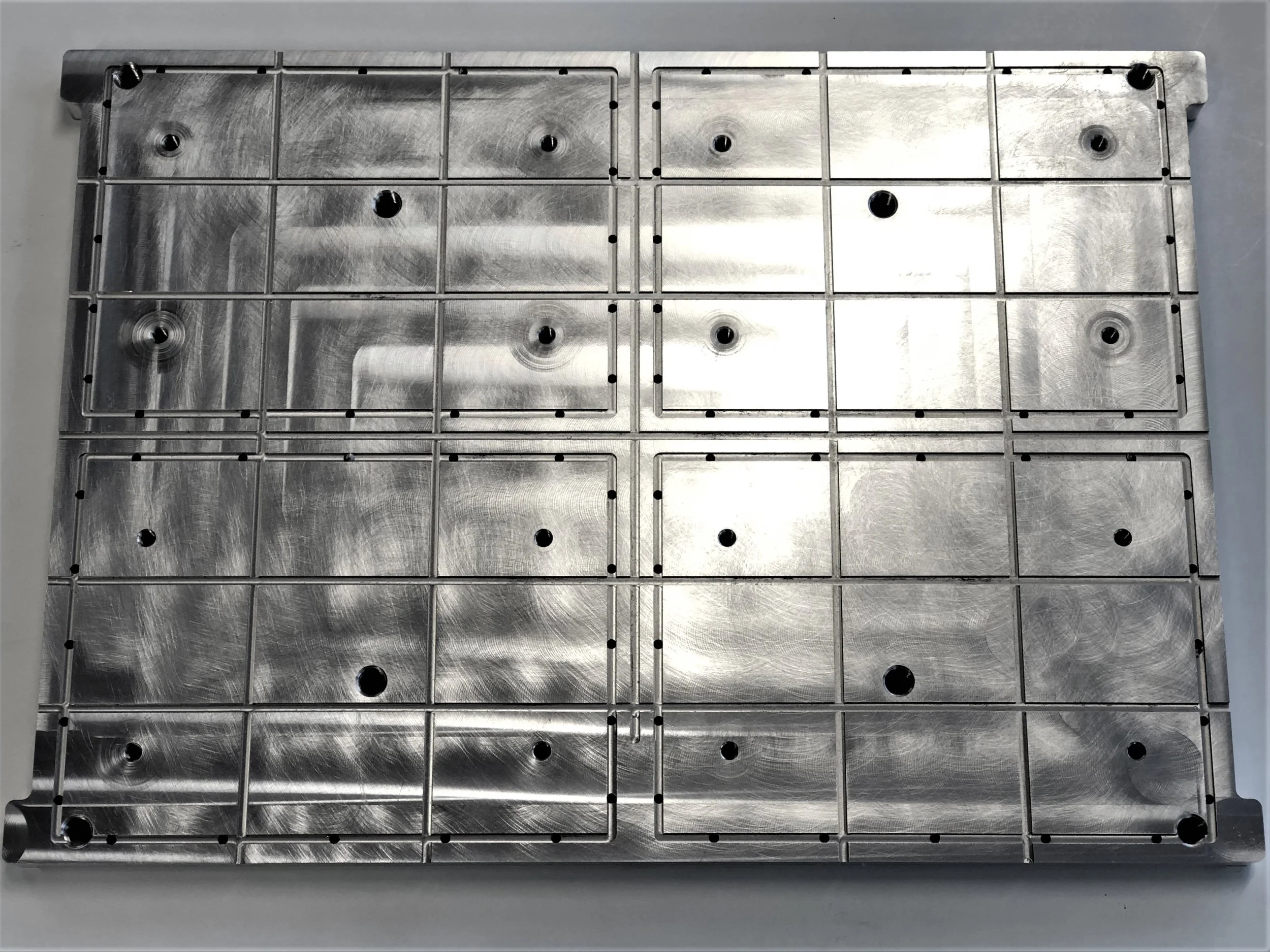

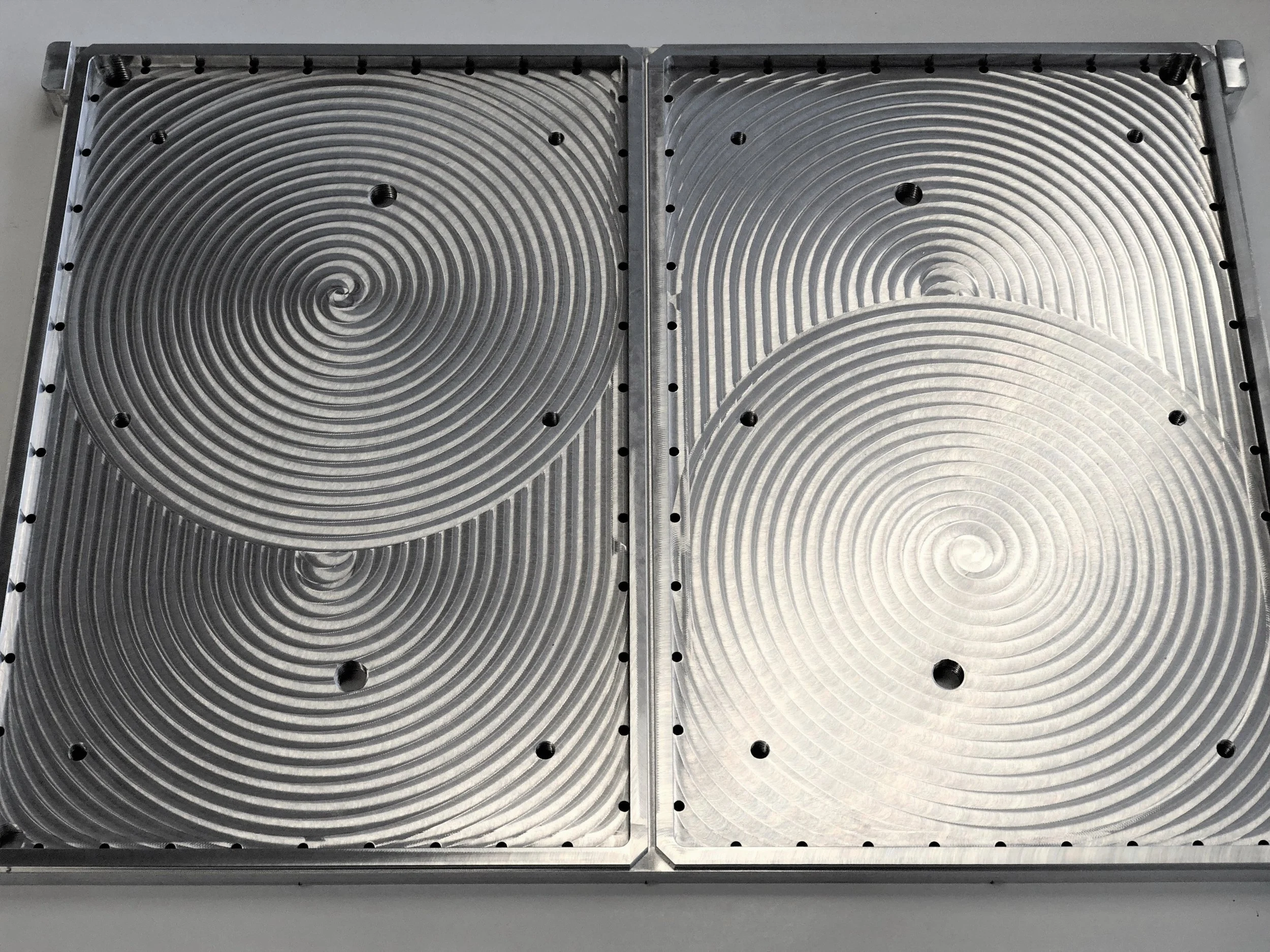

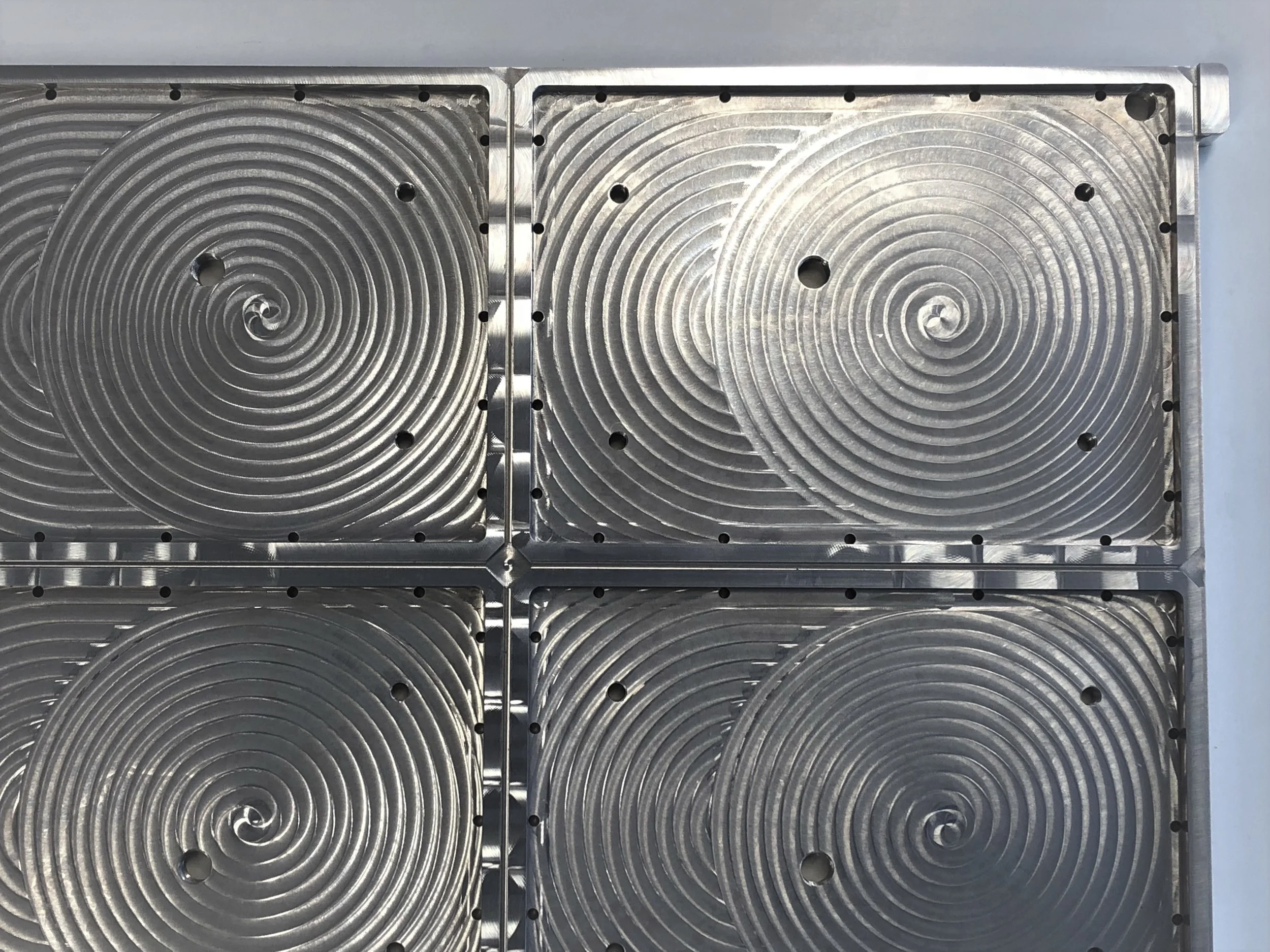

Top Ceiling Plate (4 pocket)(Back)

CNC Milling - Top Ceiling Plate (4 pocket)(Back)

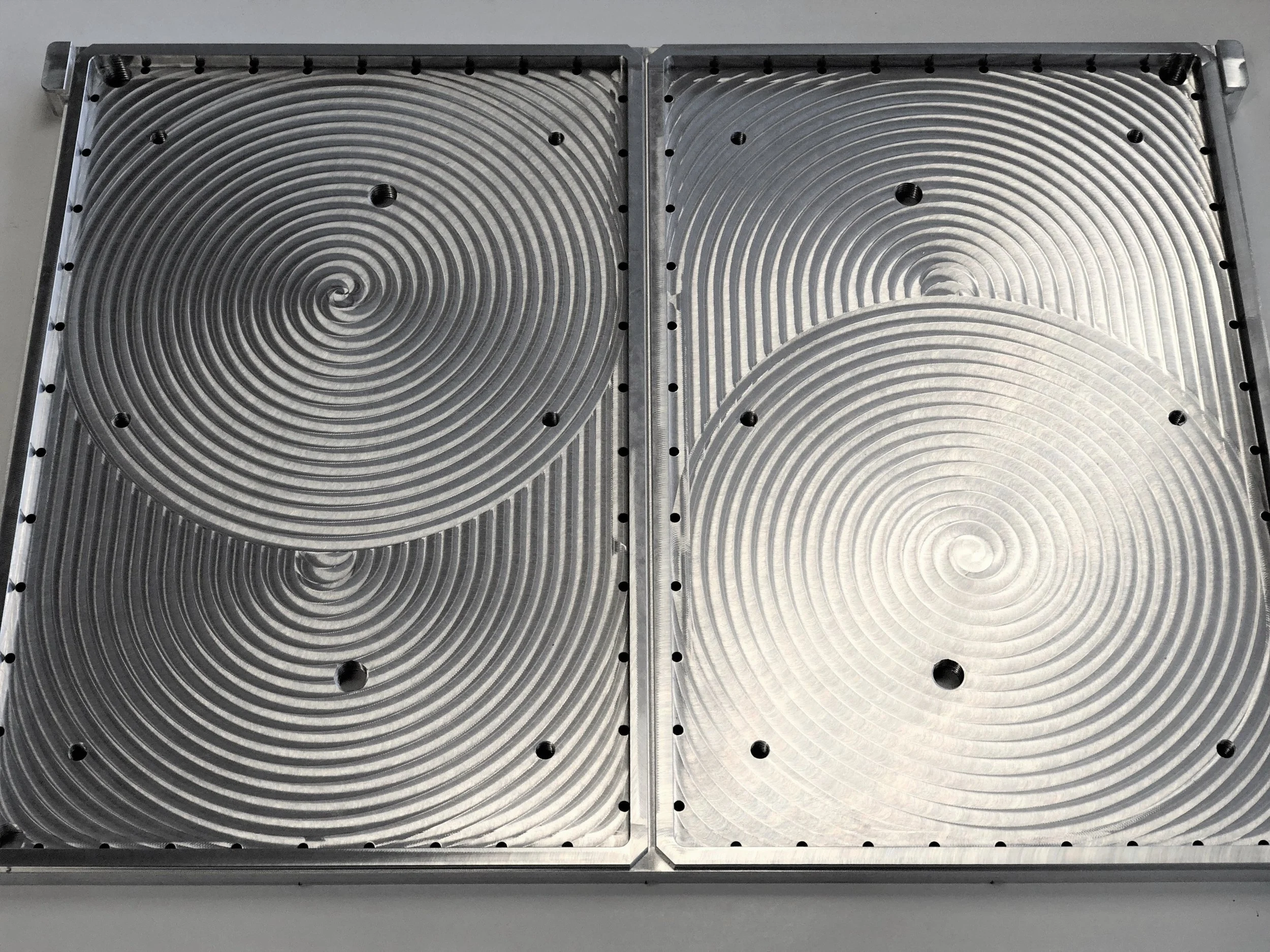

Top Ceiling Plate (4 pocket)

CNC Milling - Top Ceiling Plate (4 pocket)

Top Ceiling Plate (2 pocket)

CNC Milling - Top Ceiling Plate (2 pocket)

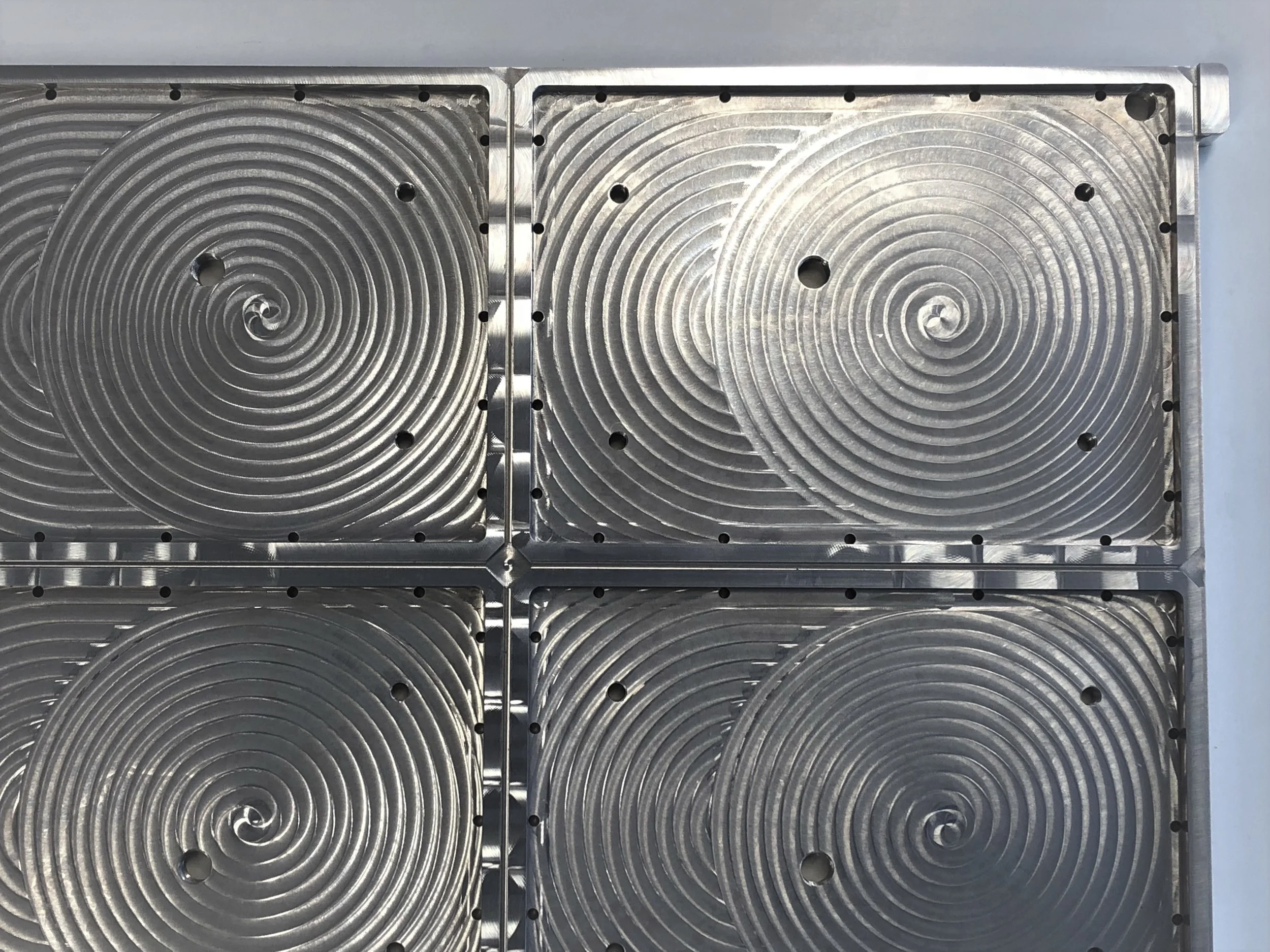

Top Ceiling Plate (close-up of machined finish)

CNC Milling - Top Ceiling Plate (close-up of machined finish)

Top Ceiling Plate (3 pocket)

CNC Milling - Top Ceiling Plate (3 pocket)

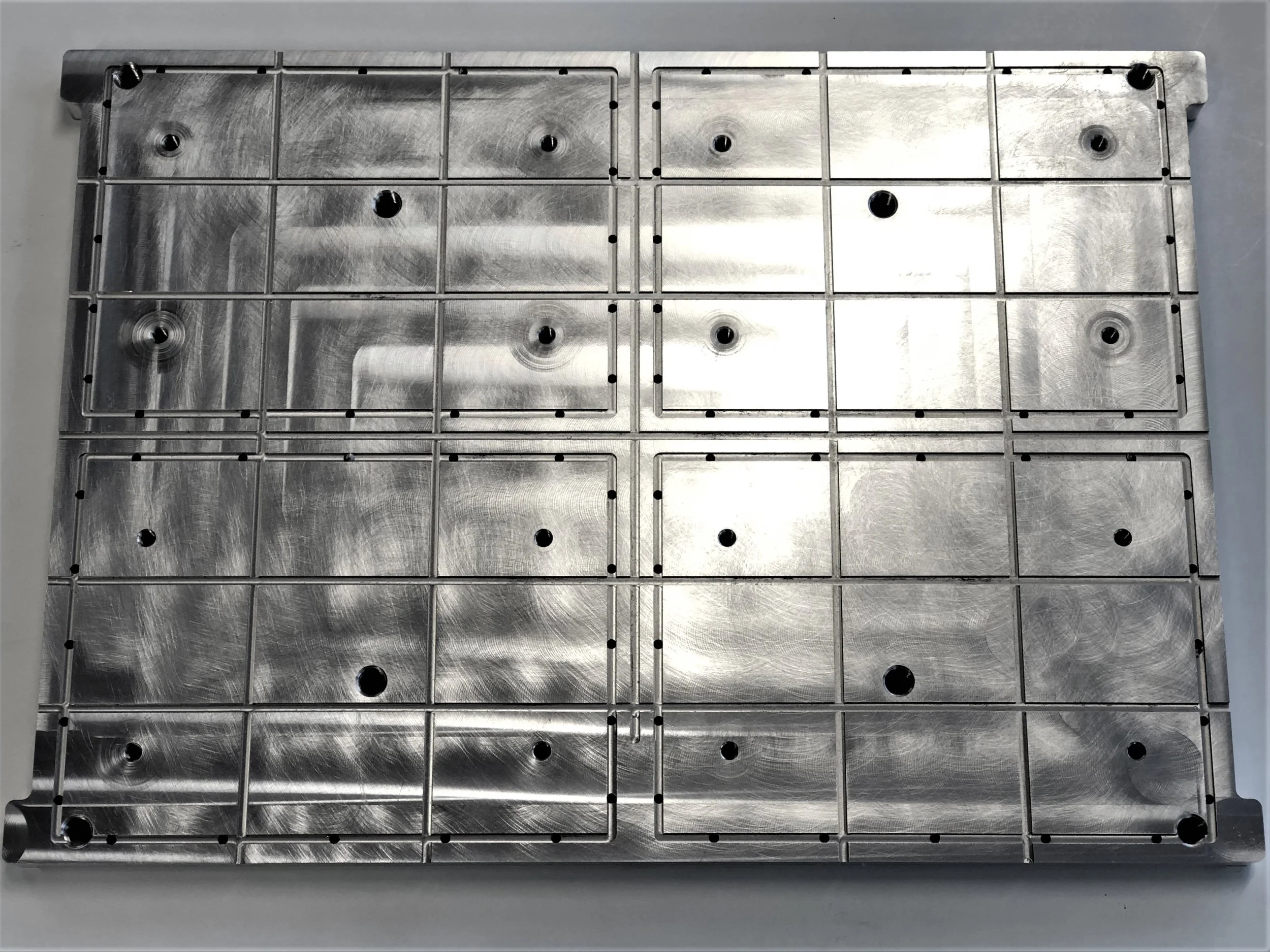

Forming Dies

CNC milling - Forming Dies (close-up of machined finish)

Forming Dies

CNC Milling - Forming Dies

Forming Dies

CNC Milling - Forming Dies

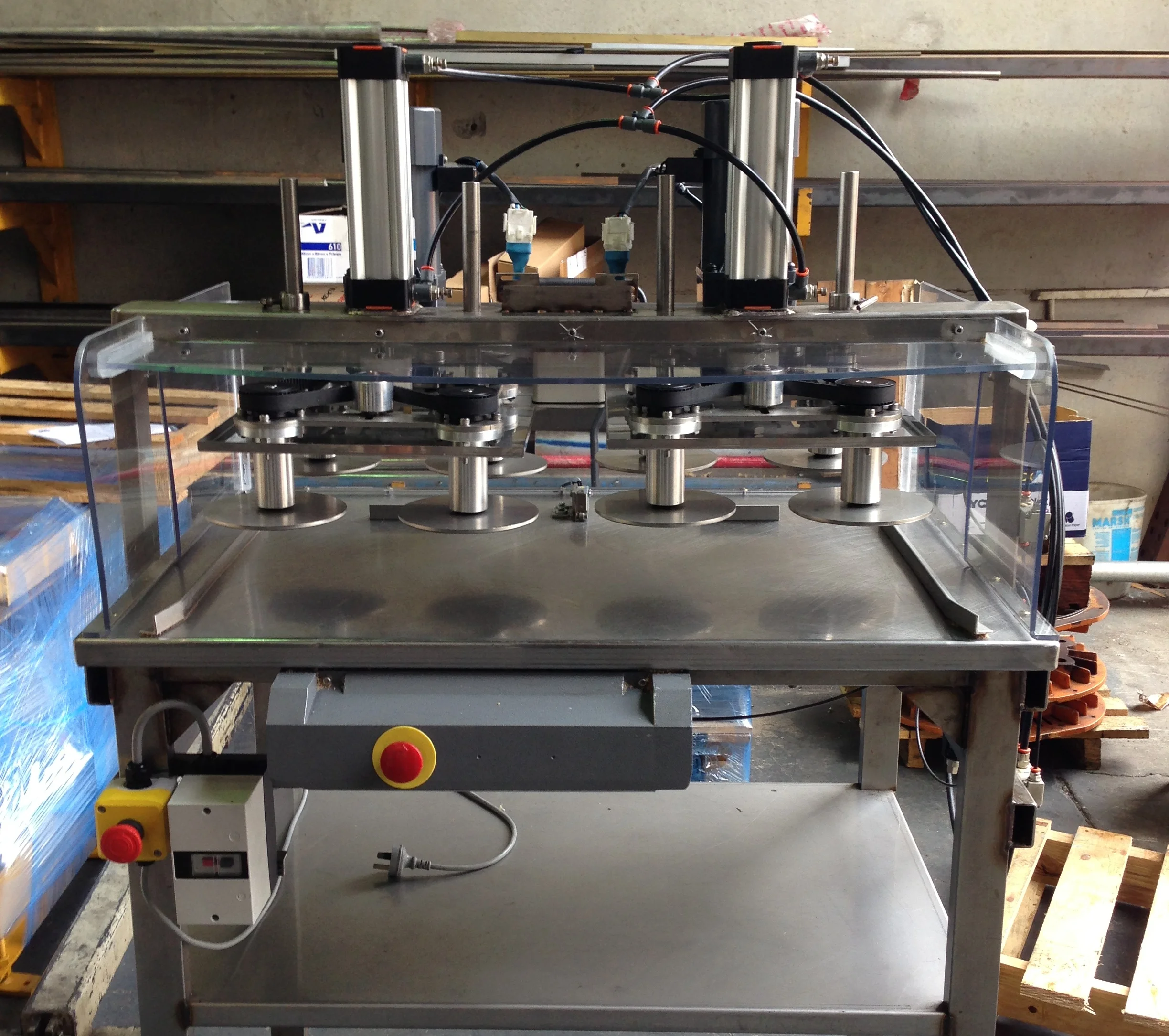

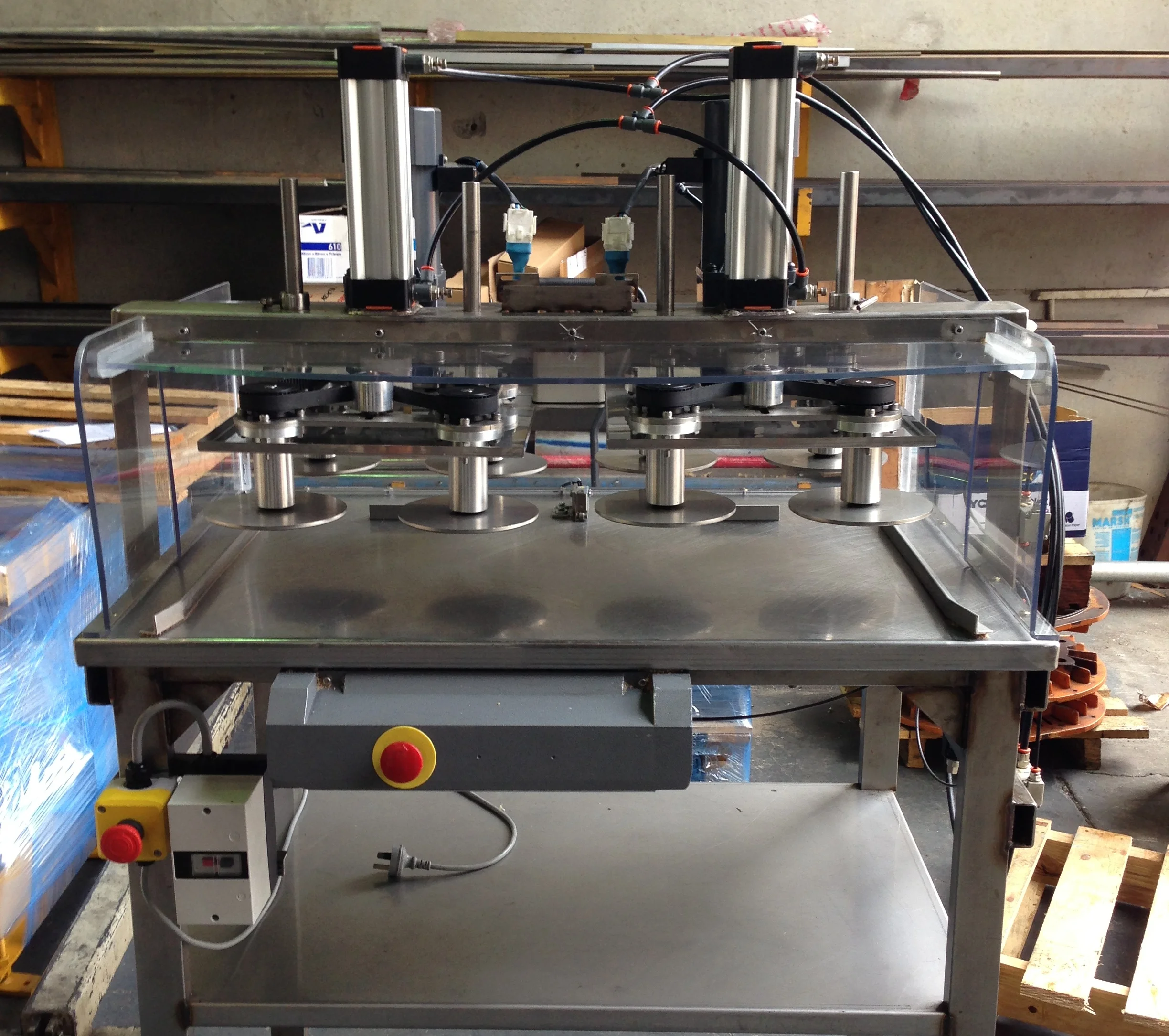

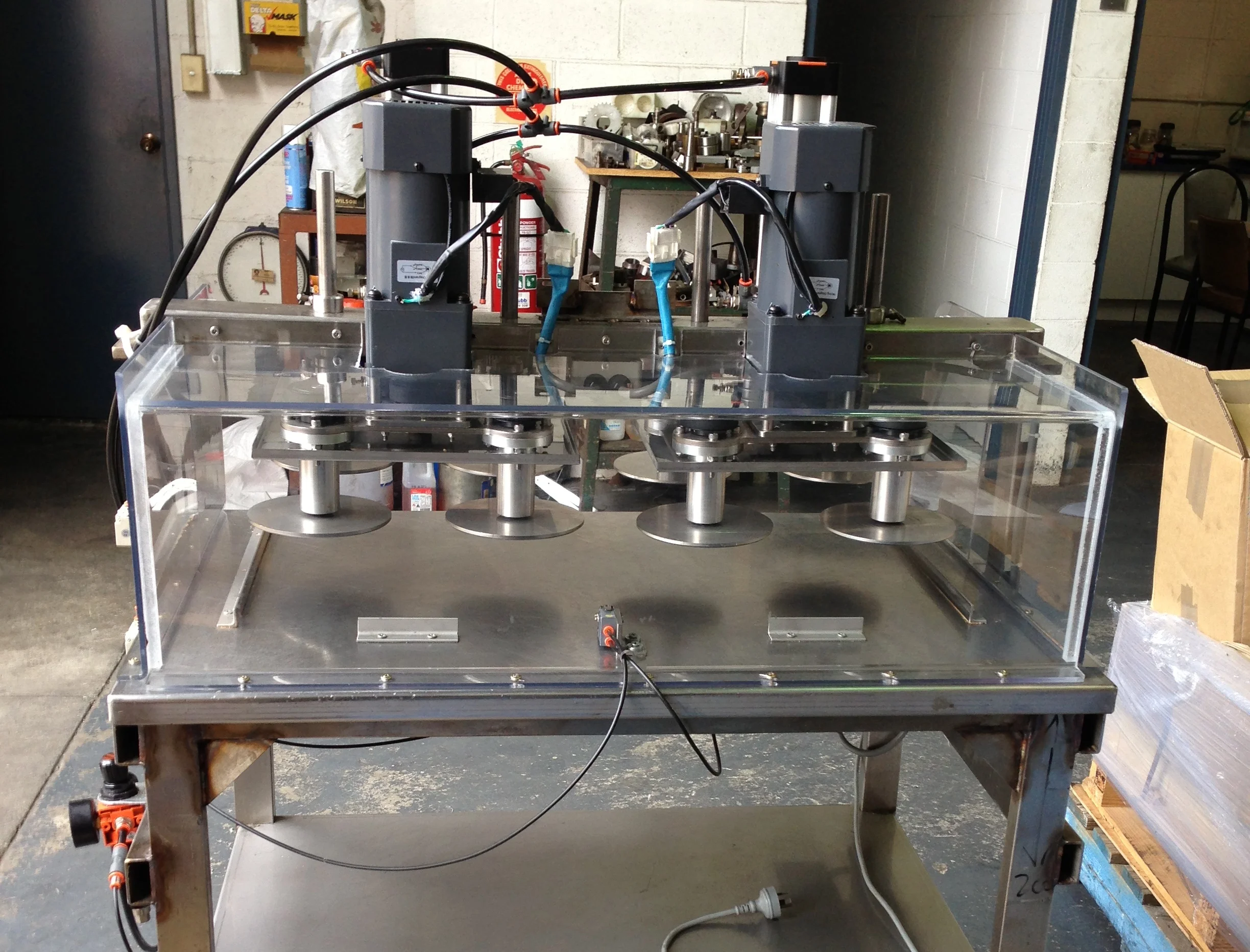

Cake Batter Press Machine

This cake batter press machine was designed and manufactured in house for our client. Our client was looking to automate a portion of their production line and engaged us to design and manufacture a solution. The job required us to work across a multiple disciplines including - CAD design, pneumatics, electrical, PLC programming, machining and fabrication.

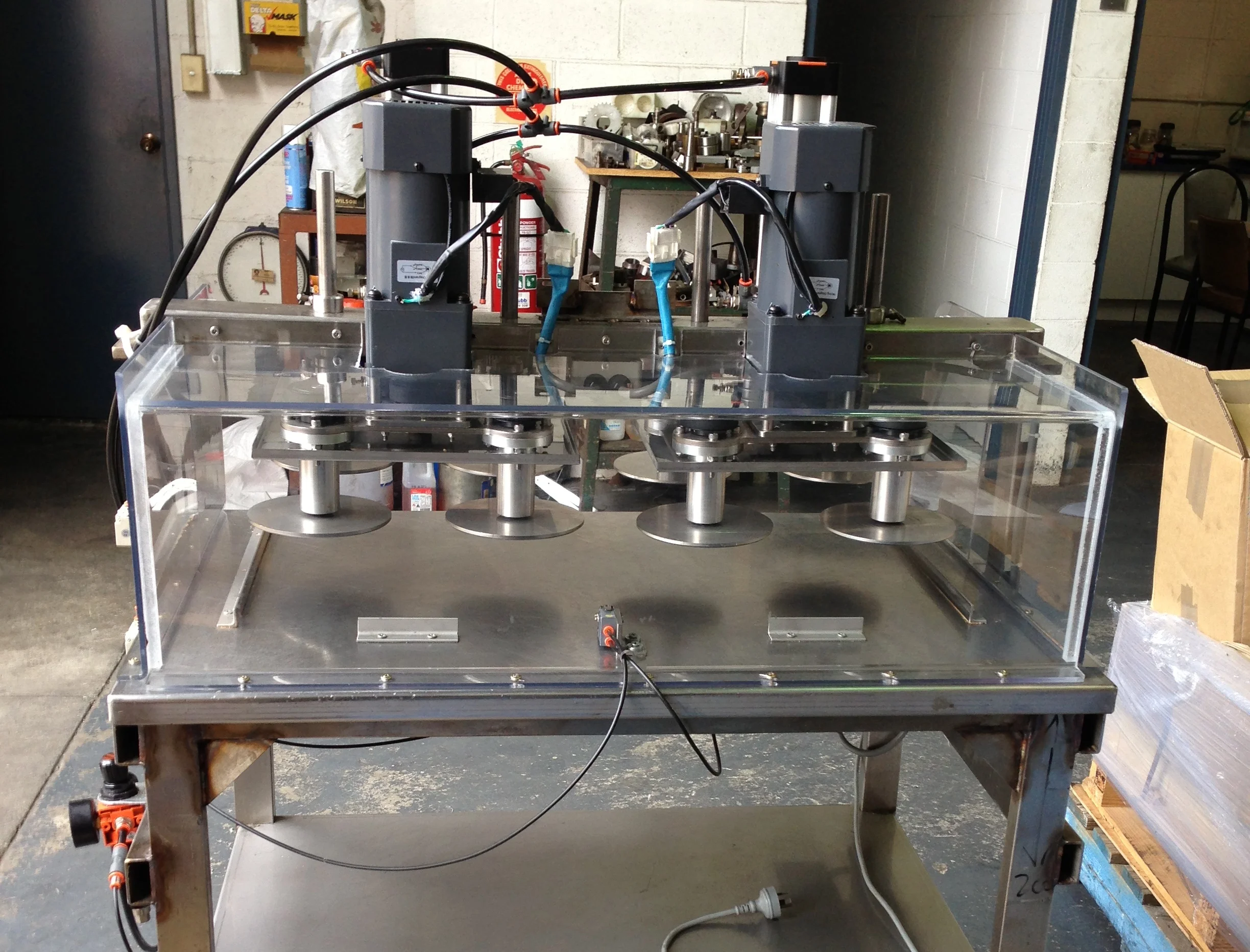

Cake Batter Press Machine

This cake batter press machine was designed and manufactured in house for our client. Our client was looking to automate a portion of their production line and engaged us to design and manufacture a solution. The job required us to work across a multiple disciplines including - CAD design, pneumatics, electrical, PLC programming, machining and fabrication.

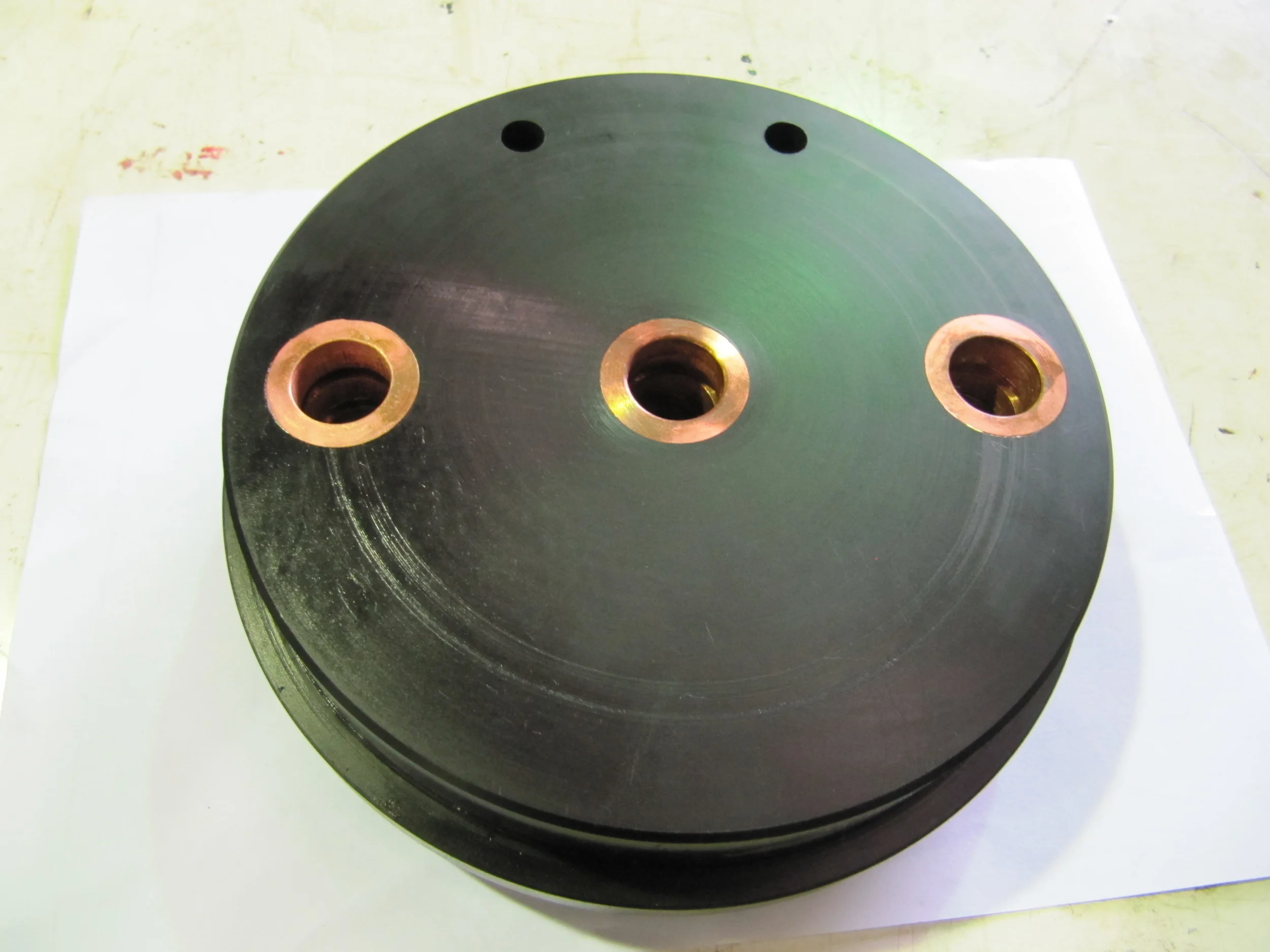

Cake Better Press Machine

This cake batter press machine was designed and manufactured in house for our client. Our client was looking to automate a portion of their production line and engaged us to design and manufacture a solution. The job required us to work across a multiple disciplines including - CAD design, pneumatics, electrical, PLC programming, machining and fabrication.